- Home Page

- Company Profile

-

Our Products

- Trolley Mounted Fire Extinguisher

- Fire System Accessories

- Hose Box

- Fire Sprinklers

- Single Door Fire Hose Box

- Fire Alarm Control Panel

- Fire Alarm

- RE-716MR MCP Push Button Type Alarm

- Smoke Detectors

- Fire Hose Pipe

- RE-716MG MCP Fire Alarm

- Fire Safety Hose Pipe

- Hydrant System

- Double Door Hose Box

- Hooter Fire Alarm

- Single Door Hose Box

- RE-716MY MCP Yellow Alarm

- Push Button Type Alarm

- MCP Fire Alarm

- MCP Red Alarm

- Hooter Cum Flasher

- Fire Bucket Stand

- Fire Bucket

- Fire Hose Reel

- Fire Extinguisher

- 4 Kg K-Type Fire Extinguisher

- 9 Kg Cartridge Type Fire Extinguisher

- 9 Kg Dcp Cartridge Type Fire Extinguisher

- ABC Cartridge Type Fire Extinguisher

- 2 Kg K-Type Fire Extinguisher

- Modular Type Fire Extinguishers

- Water Type Fire Extinguishers

- Premium 1 Kg Stored Pressure Fire Extinguisher

- ABC Cartridge And Stored Pressure Fire Extinguisher

- BC Stored Pressure Type Fire Extinguisher

- BC Stored Pressure And Cartridge Type Fire Extinguisher

- Kitchen Fire Extinguishers

- 4 Kg Clean Agent Type Fire Extinguisher

- Mechanical Foam Type Fire Extinguishers

- Fire Extinguisher Ball

- Premium 2Kg Stored Pressure Fire Extinguisher

- Premium 4 Kg Stored Pressure Fire Extinguisher

- ABC Stored Pressure Fire Extinguisher

- Dry Powder Fire Extinguisher

- Co2 Type Fire Extinguisher

- Clean Agent Fire Extinguisher

- Suppression System

- AMC Of Fire Hydrant System

- Oxygen Cylinder And Refilling Services

- Signage

- Hydrant Valve

- Fire Extinguisher Valve

- Industrial CNG Cylinder

- Contact Us

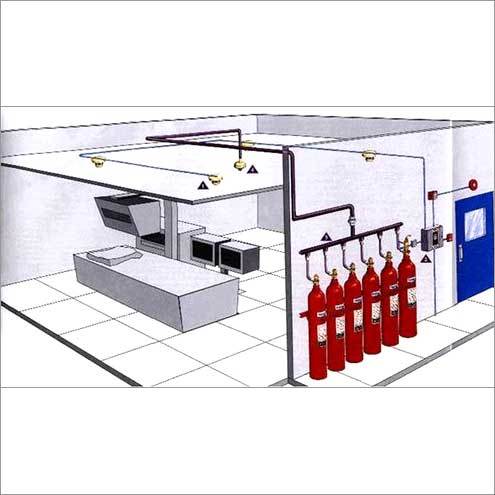

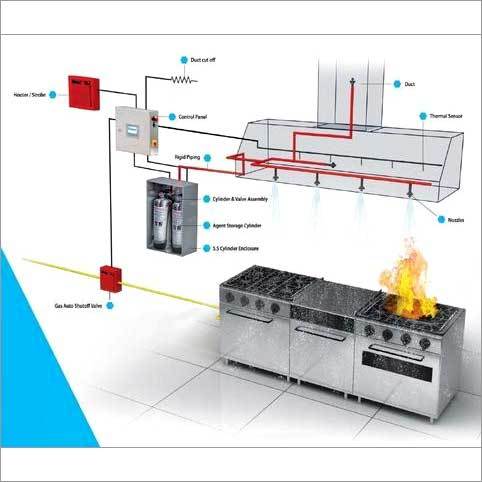

Co2 Flooding System

500000 INR/Piece

Product Details:

- Voltage 24V DC / 220V AC (For Electric Release Devices)

- Operating Pressure 55-70 bar (Depending on temperature and type)

- Installation Type Fixed System, wall/floor mounted cylinders, Piping network

- Connectivity Type Compatible with Fire Alarm Panel, Release Mechanism via Electrical & Mechanical Linkages

- Coverage Area Covers up to 300 m or as per design

- Coating Type Red Epoxy Anti-corrosive Finish

- Control Type Manual and Automatic Control (Electrical Activation, Mechanical release)

- Click to view more

X

Co2 Flooding System Price And Quantity

- 1 Piece

- 500000 INR/Piece

- Faster than 60 seconds (for total flooding)

- Flexible discharge hose, directional valves

- Pressure relief, lock-out valve, warning horns

- Manual with rearming kit

- Heat/smoke detector with alarm panel integration

- High (rapid suppressant release)

- Galvanized/Schedule 40 steel pipe

- UL, FM, IS:15222 Certified, CE Marked

- Yes, for pre-discharge warning

- 360 dispersal, high-velocity discharge

- Indoor sheltered from direct sunlight

- Pneumatic, electric, or manual lever

- Routine hydrostatic test required

- Based on protected volume calculation

- Red (standard)

- No residue, no ozone depletion

- Seamless steel

- 0C to +50C

Co2 Flooding System Product Specifications

- Automatic / Manual Total Flooding CO2 Gas Discharge

- 10 kg to 45 kg per cylinder (multiple cylinder banks as per risk)

- Wall/Floor Mounted (Skid or Stand framework available)

- Cylindrical Cylinders

- -20C to +55C

- Manual and Automatic Control (Electrical Activation, Mechanical release)

- Non-corrosive, Leaves no residue, Electrically non-conductive, Fast discharging, Pre-engineered, Highly reliable

- 55 bar (Stored Pressure), 70 bar (Working Pressure)

- Red Epoxy Anti-corrosive Finish

- Covers up to 300 m or as per design

- Industrial Fire Suppression, Electrical Rooms, Chemical Storage, Server Rooms

- Custom as per system design (typically cylinder sizes from 140 mm to 267 mm)

- Fixed System, wall/floor mounted cylinders, Piping network

- 24V DC / 220V AC (For Electric Release Devices)

- 55-70 bar (Depending on temperature and type)

- Compatible with Fire Alarm Panel, Release Mechanism via Electrical & Mechanical Linkages

- CO2 Flooding System (Gaseous Suppression)

- Class B, Class C, and Electrical Fires

- Up to 45 kg/sec depending on system

- Not Applicable (Mechanical System)

- Faster than 60 seconds (for total flooding)

- Flexible discharge hose, directional valves

- Pressure relief, lock-out valve, warning horns

- Manual with rearming kit

- Heat/smoke detector with alarm panel integration

- High (rapid suppressant release)

- Galvanized/Schedule 40 steel pipe

- UL, FM, IS:15222 Certified, CE Marked

- Yes, for pre-discharge warning

- 360 dispersal, high-velocity discharge

- Indoor sheltered from direct sunlight

- Pneumatic, electric, or manual lever

- Routine hydrostatic test required

- Based on protected volume calculation

- Red (standard)

- No residue, no ozone depletion

- Seamless steel

- 0C to +50C

Co2 Flooding System Trade Information

- 1000 Piece Per Day

- 3-4 Days

Product Description

Experience blue-ribbon fire protection with our Co2 Flooding System, imposing a triumphant standard in industrial fire suppression. Personalise your shield with seamless steel cylinders, a 360 high-velocity nozzle, and rapid discharge, extinguishing flames in less than 60 seconds. The system is compatible with integrated alarm panels, while its pressure relief and lock-out valves ensure safety. Savings emerge with no residue, zero ozone depletion, and minimal downtime. Enjoy promotional flexibility in design, coverage up to 300 m, and custom cylinder diameters. Certified UL, FM, IS:15222, CE, for total peace of mind.

Imposing Features and Versatile Applications

The CO2 Flooding System, with its robust, non-corrosive, red epoxy-coated seamless steel cylinders, offers highly reliable fire suppression suitable for industrial environments. Designed for both manual and automatic activation, it covers large surface areasup to 300 mwith high-speed, 360 gas dispersal. It is ideal for use in electrical and chemical storage rooms, server centers, and sensitive installations where residue-free, non-conductive suppression is imperative for protecting valuable equipment and personnel.

Certifications, Export Markets, and Sample Policy

Our CO2 Flooding System holds UL, FM, IS:15222, and CE certifications, ensuring the highest international safety standards for your shipped goods. Supported in domestic mar and major export destinations, our distributor and supplier channels swiftly deliver globally. Shipped products include comprehensive manuals and routine maintenance guidelines. Samples are available upon request, giving you a hands-on impression prior to a full order, guaranteeing confidence and satisfaction before shipment.

Imposing Features and Versatile Applications

The CO2 Flooding System, with its robust, non-corrosive, red epoxy-coated seamless steel cylinders, offers highly reliable fire suppression suitable for industrial environments. Designed for both manual and automatic activation, it covers large surface areasup to 300 mwith high-speed, 360 gas dispersal. It is ideal for use in electrical and chemical storage rooms, server centers, and sensitive installations where residue-free, non-conductive suppression is imperative for protecting valuable equipment and personnel.

Certifications, Export Markets, and Sample Policy

Our CO2 Flooding System holds UL, FM, IS:15222, and CE certifications, ensuring the highest international safety standards for your shipped goods. Supported in domestic mar and major export destinations, our distributor and supplier channels swiftly deliver globally. Shipped products include comprehensive manuals and routine maintenance guidelines. Samples are available upon request, giving you a hands-on impression prior to a full order, guaranteeing confidence and satisfaction before shipment.

FAQs of Co2 Flooding System:

Q: How does the CO2 Flooding System activate in case of fire?

A: The system can be triggered automatically by integrated heat or smoke detectors, or manually through a lever or electrical switch for immediate response.Q: What advantages does this system offer over traditional extinguishing methods?

A: The CO2 Flooding System provides rapid, residue-free suppression, minimizing equipment downtime and offering effective coverage for electrical, chemical, and industrial fires without harming sensitive surfaces.Q: When is hydrostatic testing or routine maintenance required for the system?

A: Routine hydrostatic tests and periodic inspections are required per manufacturer guidelines and local fire codes to ensure system integrity and performance reliability.Q: Where is the CO2 Flooding System most effectively installed?

A: Its best installed indoors in sheltered environments, such as electrical rooms, server areas, and chemical storage spaces, away from direct sunlight or harsh outdoor conditions.Q: What is the process for resetting the system after discharge?

A: After activation, the system requires manual resetting using a rearming kit to restore it to operational readiness, ensuring continued fire protection.Q: How does the integrated alarm system enhance safety?

A: The built-in alarm offers pre-discharge warnings, ensuring timely evacuation and added protection for personnel before the suppressant is released.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese